Our products are raw chemical materials that are hidden in our daily lives. They do not stand out but we have been making raw materials used in product that contributes to people’s daily lives and developing variety of chemicals to meet with the changing demand in the society and in our lifestyles.

The Taisho Era (1922): The rise of demand for Zinc

The history of Honjo Chemical dates back to 1922 in the Taisho era after WWI.

At that time, shipbuilding in military plants and demand of iron and steel manufacturing sharply increased, and the zinc business producing zinc iron sheets flourished creating a new domestic market.

Unfortunately, Japan’s zinc smelting technology was not yet fully established; also, there were no option but to import highly-priced zinc ingots from abroad which caused the domestic industry to lag behind and the society was struck hard.

Sukeo Honjo, the founder, established Honjo Zinc Industry Company in 1922 in Ohiraki, Fukushima-ku, Osaka City, in the midst of this growing demand for zinc in Japan, and it was the first company to manufacture zinc dust in Japan.

In the early days of production, zinc dust was initially used as a reducing agent of organic chemical reaction. Zinc dust application, subsequently, expanded as an ingredient for heavy anti-corrosive paints coated on bridges and marine containers.

The history of Honjo Chemical is the same path with the development path of secondary zinc products including zinc oxide in Japan.

- 1922

- Sukeo Honjo founded “Honjo Zinc Industry Company” in Ohiraki, Fukushima-ku, Osaka City.

- 1930

- Start of Yodogawa Plant

- 1934

- Restructured as a stock company.

- Start of manufacture and sale of zinc dust /distilled zinc ingots.

- 1949

- Start of manufacture and sales of zinc oxide.

- 1955

- Start of manufacture and sale of lithium related products.

- 1956

- World’s first manufacturing and sales of synthetic taurine.

- 1957

- Start of Neyagawa Plant.

- 1959

- Start of manufacture of lithium at Neyagawa plant.

The 1960s: Widespread of Color Television and demand for Strontium

Japan’s first commercial broadcasting on cathode-ray tube television began in 1953 and color television broadcasting began in 1960.

The color television, one of the significant inventions of the 20th century, was called the 3Cs in Japan (automobile car, air cooling system, and color television) and was a luxury item too expensive to penetrate into people’s lives at that time.

In such a historical context, Honjo Chemical started manufacturing strontium compounds.

Strontium was used to block the X-rays emitted from TV’s cathode-ray tubes. Later, the 1964 Tokyo Olympics and the boom of Japan’s rapid economic growth led to higher demand for strontium as color television production increased in Japan. Moreover, strontium application expanded in various use such as solar panels, ferrite magnets, semi-conductor capacitors, and other electronic material-related applications.

Currently, the company has a marketing partnership with Kandelium Barium Strontium GmbH & Co. KG to import and sell strontium materials in Japan.

- 1963

- Entered into a technical and distribution partnership with Lithium Corporation of America (now Livent Corporation) in the lithium business.

- 1967

- Company name changed to “Honjo Zinc Corporation”.

- 1968

- Start manufacture of strontium salts.

- 1970

- Renamed the company to “Honjo Chemical Co., Ltd.”

- 1971

- A joint venture company, Asia Lithium Corporation, was formed between Lithium Corporation of America (now Livent Corporation).

- 1972

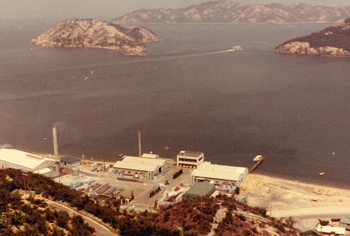

- Start of Naoshima Plant

- 1973

- Start manufacture of lithium bromide at Naoshima Plant.

- 1979

- Manufacturing of zinc dust and zinc oxide was transferred from Osaka to Naoshima Plant.

- Start manufacture and sales of high-purity strontium carbonate and conductive zinc oxide.

1980s: The spread of Mobile Phone and increase demand of Lithium

Honjo Chemical was the first company in Japan to manufacture and sell lithium salts in 1955. Lithium played an important role in the development of global electronic devices including the spread of mobile phones which have become an indispensable device in people’s daily lives.

There are two methods to produce lithium–one is to purify salt lake water and the other is to crush and extract lithium ore. Honjo Chemical’s Neyagawa Plant started lithium production in 1959 using the extraction method from lithium ore. Thereafter, a lithium foil for lithium batteries used in coin cell batteries and other applications were developed using proprietary technology in 1980.

The first portable phone devise was introduced in 1985, but it weighed about 3 kg. In 1987, a handheld cell phone was introduced but the weight was about 900g still far from being portable. The lithium-ion battery, the first rechargeable battery to be commercialized in 1991, overcame this problem.

Lithium is the lightest of all metallic elements, and lithium-ion batteries have high density while being light and compact; thus, it was possible to reduce the weight of batteries.

Honjo Chemical was one of the first companies to start manufacturing and selling cathode materials for lithium-ion batteries in 1992, and the high quality of its cathode materials was highly recognized and played a tremendous role in the popularizing use of mobile phones around the world.

- 1980

- Start manufacture and sales of ultra high purity lithium carbonate (for single crystal).

- Lithium foil for lithium batteries was developed using proprietary technology and started manufacturing and sales.

- Organic compound pilot plant was constructed at Naoshima Plant to start contract manufacturing.

- 1983

- Start of manufacture and sales of organotin compounds.

- 1986

- Start manufacture of butylithium at Asia Lithium Corporation.

- The organic compound pilot plant in Naoshima was expanded and completed to become the site of the current Naoshima Organic Chemical Plant. Start manufacture of bromine compounds.

1990s: The trend toward contract manufacturing of pharmaceutical and other intermediates

There has been a major transformation in the manufacturing system in the pharmaceutical industry since the postwar to present.

In the 1960s, the pharmaceutical industry preferred integrated manufacturing process in its own factories and restricted contract manufacturing for several years.

The importance of outsourced manufacturing grew to help reduce production and pharmaceutical development costs which led to the deregulation of manufacturing practice in the Japan pharmaceutical industry.

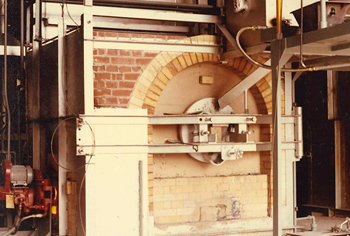

Honjo Chemical, adapting to the trend of that time, carried out a series of test operations and built an ultra-low temperature reacting facility in the Naoshima Organic Chemical Plant in 1999.

There were not many plants that had multiple ultra-low temperature reacting tanks in the same facility at that time in Japan and this breakthrough facility made it possible to adjust the temperature settings for each reaction tank. Also, ultra-low temperature solution can be transferred and dropped into adjacent reaction tanks, providing excellent reaction control.

This ultra-low temperature reacting facility produce intermediates for fine chemicals, semiconductors, and electronic materials in addition to pharmaceutical intermediates.

- 1990

- Start of manufacture and sales of monogermanic gas for semiconductor process.

- 1992

- Start of manufacture and sales of cathode positive materials for lithium-ion batteries (lithium cobalt oxide).

- 1993

- Established a joint venture, Dalian Honjo Chemical Co., Ltd., in Dalian, China and began manufacture and sales of lithium bromide.

- 1995

- Start of manufacture and sales of anode materials for lithium-ion batteries (Lithium titanium oxide).

- 1999

- Completion of an ultra-low temperature reacting facility at the Naoshima Organic Chemical Plant strengthening the manufacture of pharmaceutical intermediates.

- 2000

- Completion of production facilities for fine carbon materials such as fullerenes and carbon nanotubes.

- 2001

- Acquired ISO 14001 certification

- 2003

- Acquired ISO 9001 certification

- 2004

- Completion of the new head office building within Neyagawa Plant.

- 2008

- Completion of mass production plant to meet increasing demand for monogermanic gas.

- 2011

- Expansion of the high-purity lithium carbonate manufacturing plant within the Neyagawa Plant.

- 2014

- Expansion of ultra-low temperature reacting facility at Naoshima Organic Chemical Plant.

- 2017

- Completion of the new Naoshima administration office.

- 2024

- Completed construction of R&D Center.

Opening of the Umeda Office.